Newton Labs SW1000 Advanced Underwater Drone

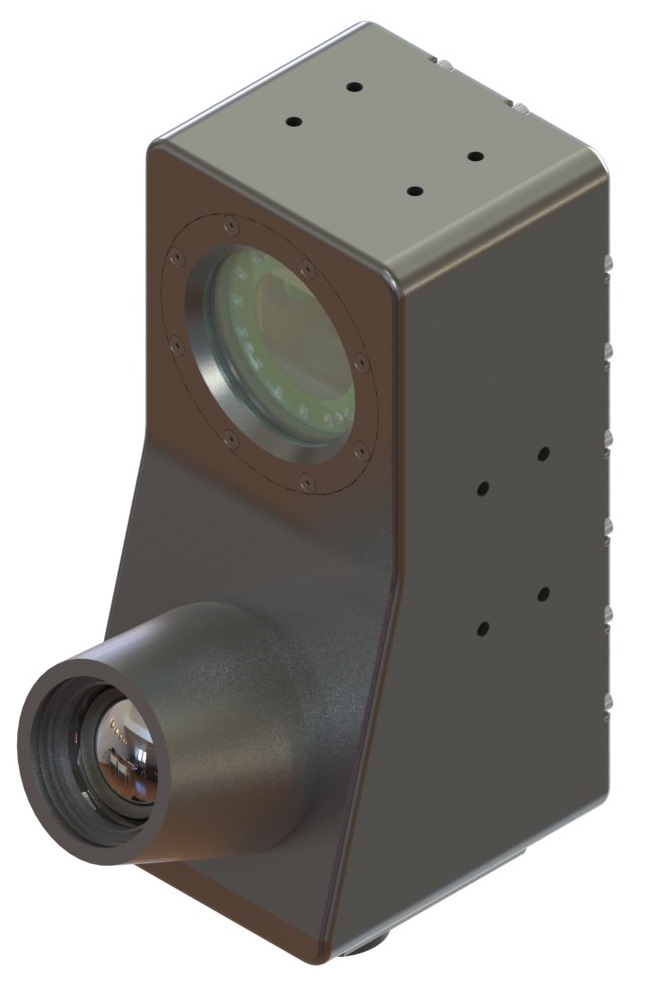

Mounted with the Newton NM200EVT-1 color nuclear underwater laser scanner

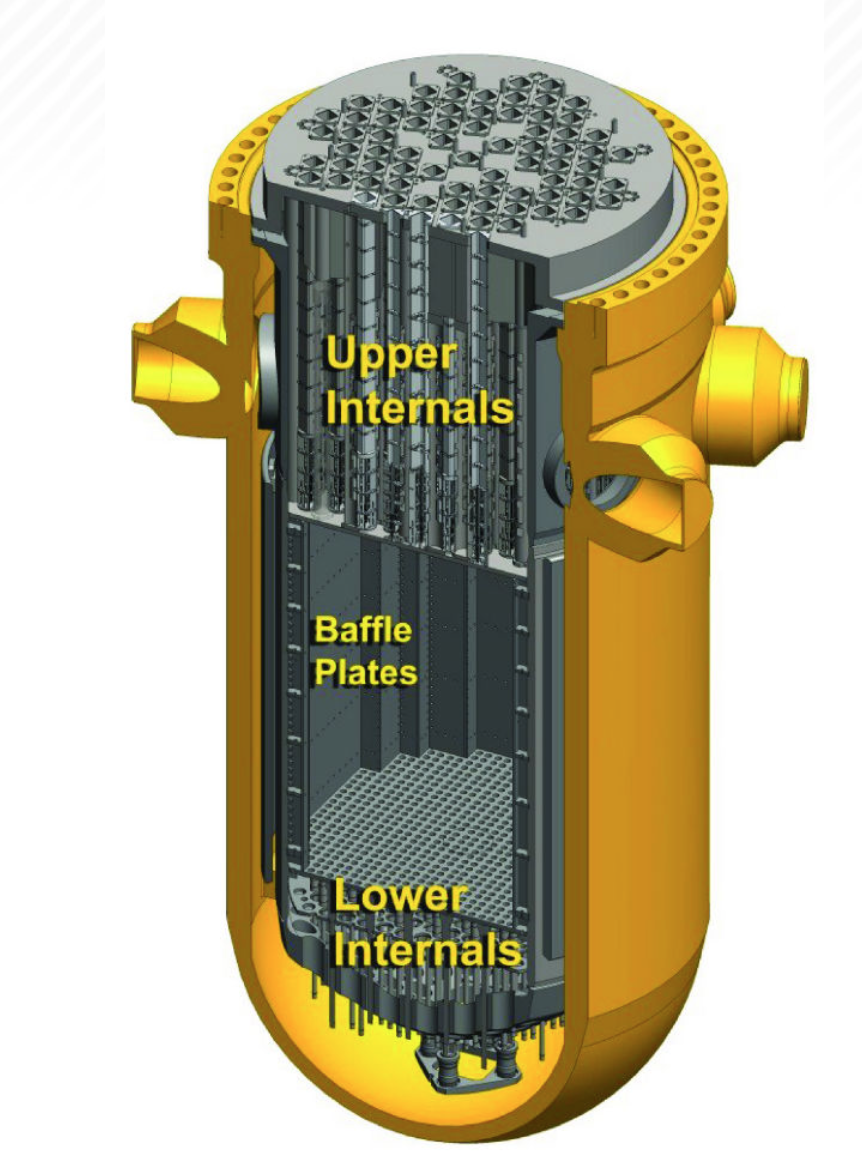

Developed Specifically for the Nuclear Power Industry to Deliver the Newton NM200EVT-1 to Satisfy MRP-227/ASME Section XI Inspections

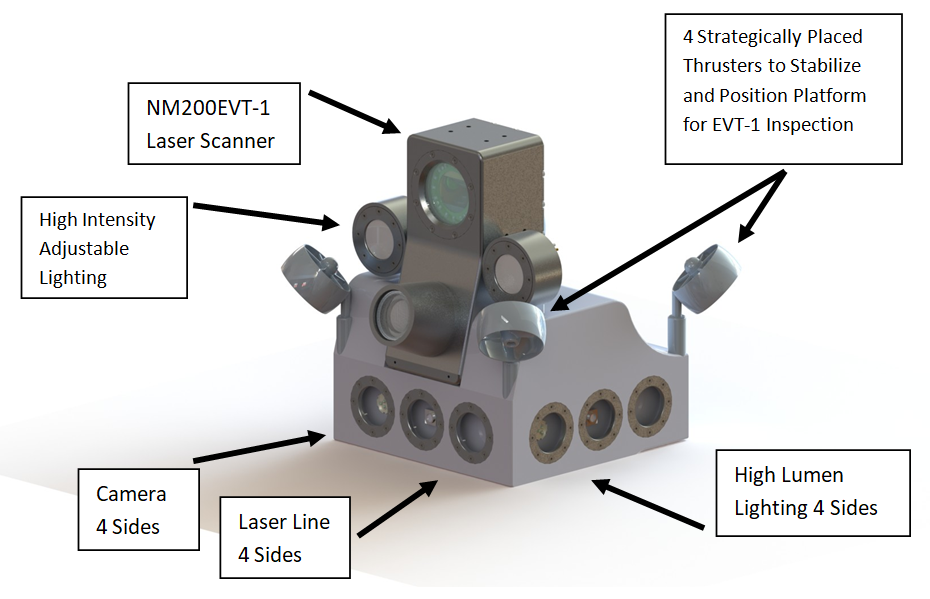

The Newton Labs Model SW1000 State of the Art Underwater Drone Platform used to deploy the NM200EVT-1 Laser Scanner to perform MRP-227 and ASME Section X1 inspections. Advanced Newton developed software (similar to the software used on air drones) controls thrusters for exact placement and stability to perform the most critical EVT-1 inspections and laser scan measurements. Newton's SW1000 Underwater Drone can be pre-programed to inspect over 90% of MRP-227 and ASME Section XI required inspections and physical measurement thus removing a significant load from the drone operator.

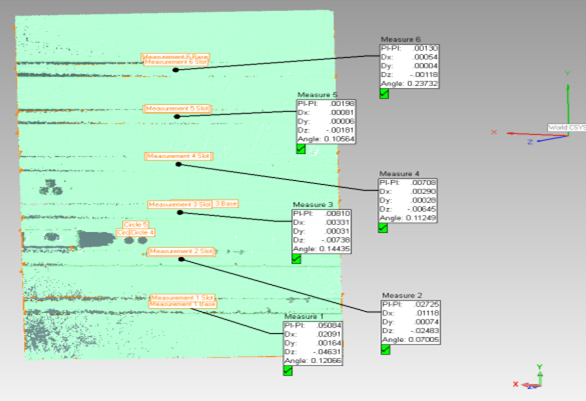

The Newton SW1000 is fully programmable and can use utility drawings to locate and then position the NM200EVT-1 scanner in the precise position to generate the required measurements and CAD models (after post processing with third party software). The SW1000 with the NM200EVT-1 can be pre-progammed to allow up to 80% to 85% of the required internal measurements thusrelievingthe operator of considerable load and greatlyspeeding up inspections.

The Newton SW1000 underwater drone has 5 high resolution cameras, 6 sets of adjustable lights and 4 laser lines in addition to the NM200EVT-1 laser scanner to allow for precise EVT-1 and other inspections. The Newton Model SW1000 is extremely easy to drive and use, requiring little or no training for utility technicians. All lighting has adjustable intensity for the difficult EVT-1 inspections.

The Newton Model SW1000 is mounted with the Newton NM200EVT-1 Laser Scanner with built-in high-resolution radiation tolerant color cameras and lighting to quickly and accurately perform VT- 3, VT-1 and EVT-1 inspections required by MRP-227/BWRVIP and ASME Section XI. In addition, the laser scanner creates high-resolution 3D CAD models (after post processing with third party software) that performs the Physical Measurements of the Effects of Degradation required MRP-227 in a fraction of the time of currently deployed technology along with much improved accuracy; thus having permanent storage of a 3D CAD model of dimensioned degradation or defects for later review.

For full details on the NM200EVT-1 Laser Scanner, please click here: Newton NM200EVT-1 Underwater Laser Scanner