For information on the Inspector

in-tank robot, please contact:

sales@newtonlabs.com

Underwater Robot Precisely Maps Water Storage Tank Floor Defects

The Inspector is a semi-autonomous, underwater robotic platform designed to deploy a variety of advanced, nondestructive evaluation (NDE) sensors to over 90% of a flat-bottom water storage tank of the type used at nuclear power plants, and to map the position of any indications with an accuracy of 1/8th inch (3 mm).

Surveying Nuclear Plant Storage Tank Integrity

Storage tanks at nuclear power plants are constructed of aluminum, stainless

steel or carbon steel, and all have naturally occurring electro-chemical processes

that can eventually

deteriorate

the metal, resulting in leaks. Defects that develop on the underside of tank

floors are particularly difficult to detect and measure.

The Nuclear Energy Institute (NEI) has recommended that all nuclear plant storage tanks undergo periodic inspection. Non-destructive evaluation (NDE) methods, such as eddy current and ultrasonic phased array are the most suitable technologies to inspect tank floor bottom plates. Using this equipment has meant taking a tank out of service by draining and ventilating it so that humans in protective clothing can enter and conduct the survey.

The Inspector Solves an Industry Problem

Inspector in-tank underwater robots perform NDE tank floor surveys

without the necessity of draining or removing a tank from service:

- Inspector robots survey and map the condition of individual tank floor plates.

- Mounting options for NDE probes includes a indexable, twin-arm module.

- The navigation system can map and store the location of defects and later return

and place a sensor at the location of a defect with an accuracy of 1/8 inch (3 mm). - Inspector robots can be deployed through a 19 inch-wide (48 cm) tank top hatch.

- Versions of the Inspector Robot are available for Diesel, Petrochemical and other fluids.

|

Newton Labs has partnered with Sonic Systems to provide the non-destructive (NDE) inspection technology for the Newton Underwater Nuclear Robotic tank inspection. This combined service will be the most advanced underwater NDE tank inspection and robotic repair service currently available in the nuclear industry. This service is now available for both water and diesel tanks. Read the press release ▶ |

Read about the Inspector navigation process of the Inspector ▶ HERE.

Read about the sensor and tool-attachment capabilities of the Inspector ▶ HERE.

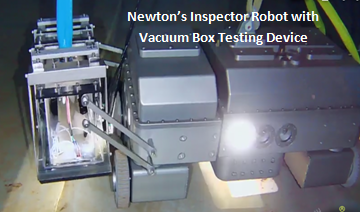

Update - Newton's Robotic Tank Inspection expands to Include Robotic Underwater Weld Vacuum Box Inspection

For many years Newton's robots have been performing Robotic Nuclear Tank Inspections and cleaning with Plate UT, Visual Inspection, Laser Scanning and Cleaning.

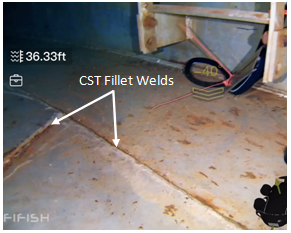

Since UT does not integrate the welds Newton has added Underwater Robotic Vacuum Box Inspection in order to confirm weld integrity. First deployed at a major utility in 2021 it adds complete inspection to CST inspection for both BWR and PWR reactors. The vacuum box is equipped with pressure gauge, cameras, and the technology to apply a vacuum pressure differential underwater. Utilizing these vacuum boxes the the Newton Team was able to identify susceptible areas in both the floor welds and the peripheral welds.

Newton's Robotic Tank Inspection can be used both On and Off Outage thus allowing significant flexibly in scheduling nuclear tank inspections.

The tank examination typically captures full UT and visual data from over 90 percent of the tank floor while the tank remains in-service and the plant online. Prior to the insertion of the robot, pre-engineering calculations are performed to ensure no degradation of the plant operating parameters and that the flows in the tank will not interfere with the inspection. Plant engineers can use the data from the complete tank floor for trending analysis over multiple inspections. With the Newton Robot's precise machine vision navigation system, the ability to return to re-inspect previously discovered defects is unsurpassed compared to spot UT checks captured by divers.

Read the press release about Robotic Underwater Weld Vacuum Box Inspection ▶ HERE.