Operating Properties of the SW1000 Advanced Underwater Drone

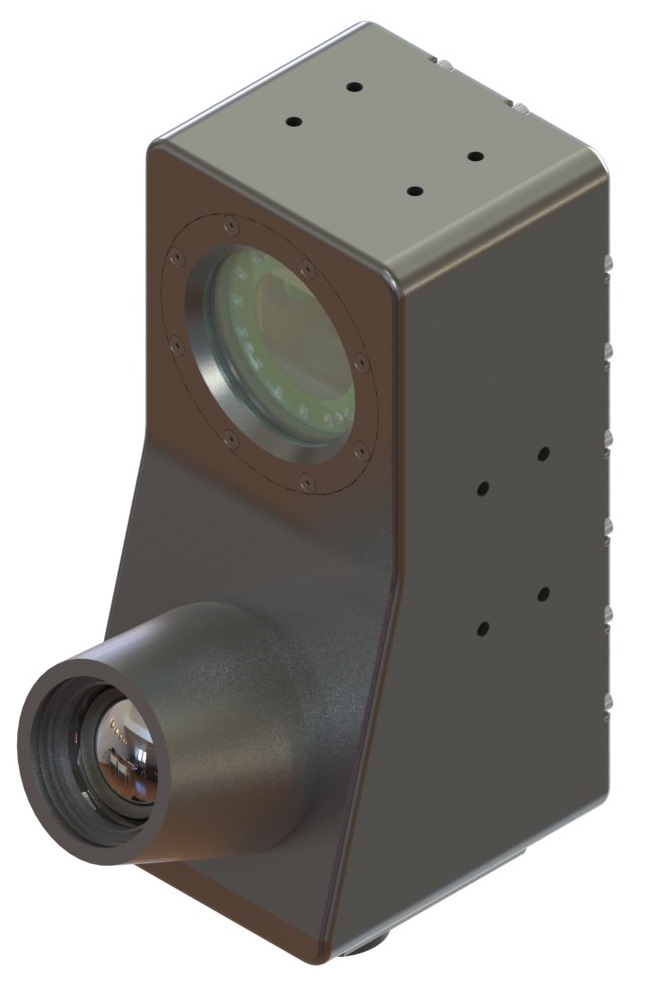

Mounted with the Newton NM200EVT-1 Color Enhanced Visual Inspection and Laser Scanner

Precise, Reliable and Efficient In-Vessel Inspection and Dimensioning

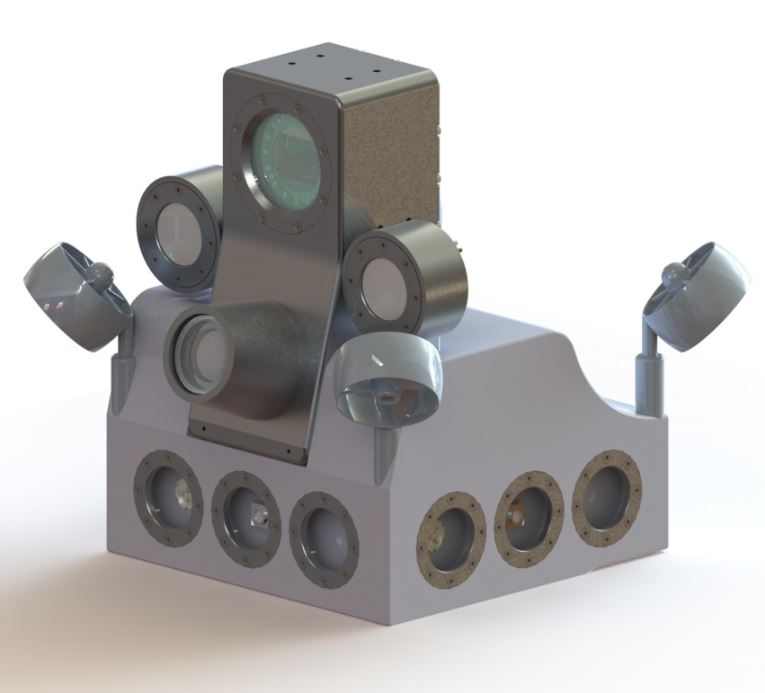

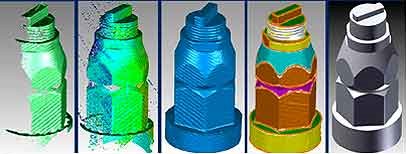

Nuclear plant operators need precise measurements of as-built components located in-vessel and in the pools, or other underwater plant locations. These componets or surfaces need to be inspected in order to track cycle-to-cycle degradation and to obtain measurements of components in order to achieve a correct fit for fabricated replacement parts.The SW1000 Nuclear Underwater Drone with the NM200EVT-1 camera/scanner provides an advanced method of taking those measurements.

In-air laser scanners have existed for several years, but precise underwater laser scanning is much more challenging, especially within PWRs and BWRs. Newton-developed software makes underwater laser scanning possible in this environment by mitigating water turbulence, heat and radiation while producing a point cloud of great detail and density.

T he SW1000 Advanced Nuclear Drone allows for precise stable positioning of the NM200EVT-1 camera/scanner using similar techonogy to that employed on many air drones. The SW1000 can postion the NM200EVT-1 precisely in any orentation within the reactor to allow for the aquisition of pictures and scanns. Newton-developed positioning software makes underwater high resoution pictures and laser scanning possible in this environment. In additon, the Newton software allows for pre-progaming of the postions to aquire the pictures and measurements removing much of the load requirements from the operator

Operational Characteristics

- The SW1000 uses precise positoning software to hold position during the aquasition of pictures and laser scanning.

- The SW1000 mounted with the NM200EVT-1 laser scaner is able to scan a target as close as 6 in. (150mm) and out to a distance of almost 3 ft. (0.9M) for a scan coverage area of 2.1 ft. x 2.9 ft. (64 cm x 88 cm).

- The NM200EVT-1 laser scanner mounted on the SW1000 is designed to scan and capture much larger target areas by combining several point clouds together to form larger composites.

- The laser scanningsystem measures underwater targets to an accuracy of +/-.003 (0.067mm) while the color Enhanced Visual Inspection satisfies the requirements for MRP-227/ASME Section XI.

- In the visual observation mode, the fully controllable high-intensity LED ring array on the head illuminates the area and the ultra high-definition color camera transmits a color image to the control console screen to assist the operator for optimum positioning and visual inspection.In additon the SW1000 includes 4 other controllable lights to assist in visual inspection

- The control console powers and communicates with the SW1000 and NM200EVT-1 scanner through a cable via low-voltage DC power and signals, and the SW1000 sends control signals, pictures and scan results up via Gigabit Ethernet.

- All data aquiured by the SW1000 and the NM200EVT-1 is permanently stored for later analysis and study.

For full details on the NM200EVT-1 Laser Scanner, please click here: Newton NM200EVT-1 Underwater Laser Scanner