SW1000 Advanced Nuclear Underwater Drone

Mounted with the Newton NM200EVT-1 Laser Scanner with Enhanced Color Visual Inspection

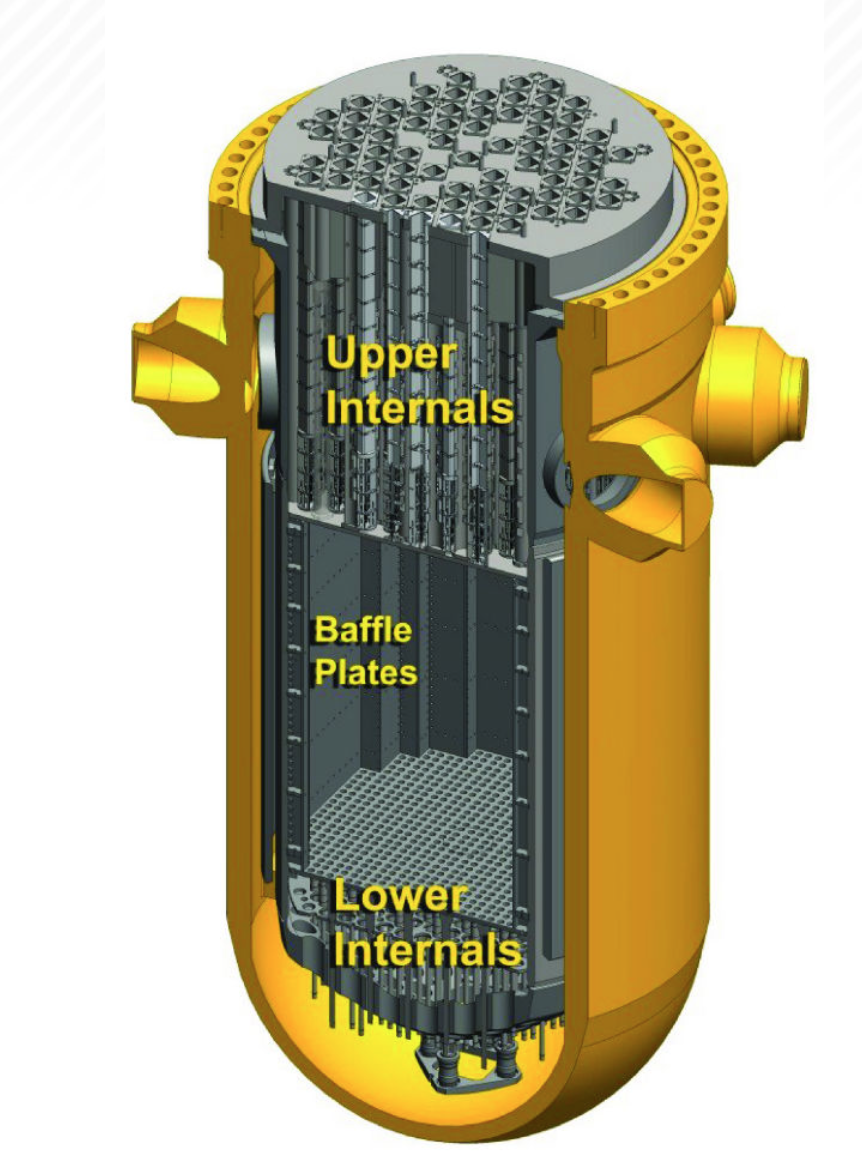

Developed Specifically for the Nuclear Power Industry to Satisfy MRP-227/ASME Section XI Inspections

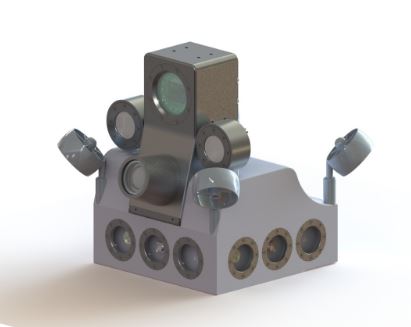

The SW1000 mounted with the NM200EVT-1 nuclear underwater laser scanner is a new accompaniment to Newton's world leading underwater nuclear scanning technology. This underwater drone is not only self-stabilized and pre-programmable but also allows operation in any orientation to best inspect reactor components. It is also much smaller than most competing underwater nuclear swimmers, and much easier to control with Newton's built in operation and stabilizing software. Similar to current air drone technology, its powerful thrusters accommodate most external flows that may be found in the reactor. This new tool adds remote positioning and color EVT-1 Enhanced Visual (as well as VT-1 and VT-3) capability to the Newton's nuclear underwater scanning capability.

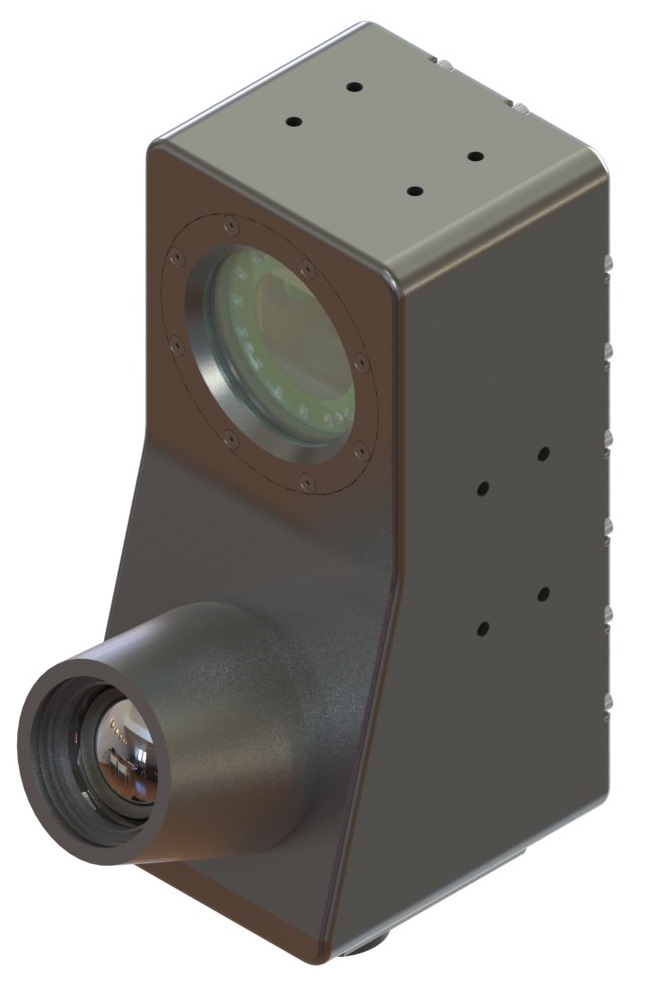

The mounted NM200EVT-1 Nuclear Underwater Laser scanning system combines rugged, industrial-grade hardware and electronics with sophisticated, Newton-developed software that mitigates the disruption of turbulence, heat, and radioactivity characteristics of the in-vessel environment.

The laser scanner has a demonstrated accuracy of 0.003" (0.076mm) or better, and is designed to work in concert with industry standard, three-dimensional software, producing a point cloud output so dense and detailed that a fully measurable CAD model can be generated.

The capability of the NM200EVT-1 to provide precise, reliable and efficient dimensioning of as-built features as well as providing MRP-227 Enhanced Visual Inspection to track cycle-to-cycle degradation can be important to nuclear utility operators.

Components of the SW1000 system:

- The SW1000 is fully pre-programmable to allow approximately 80 to 90% of reactor internals inspections without operator intervention

- The SW1000 includes 4 additional cameras and 4 additional high intensity adjustable lights

- The SW1000 has side mounted laser lines to eliminate collision

- The NM200VT-1 scanning head encloses a ultra-high resolution video camera and a controllable output high-intensity LED ring array

- The NM200EVT-1 camera is native 2048 X 1536- 3 Megapixel high resolution color camera that easily exceeds the requirements of EVT-1

- The NM200VT-1 light is a fully controllable output high-intensity white LED ring array

- The SW1000 console unit contains the SW1000 and NM200EVT-1 outputs and controls, flat panel screen and keyboard

- The Control Console contains both the SW1000 controls and NM200EVT-1underwater scanning software

For full details on the NM200EVT-1 Laser Scanner, please click here: Newton NM200EVT-1 Underwater Laser Scanner