|

The NM200E Core Verification System is now sold and serviced by

*This technology enabled Exelon Nuclear to wins

the Nuclear Energy Institute's 2012 Top Industry Practice (TIP) Award in the

Maintenance Category for

“PWR Fuel Alignment Mapping

System.”

|

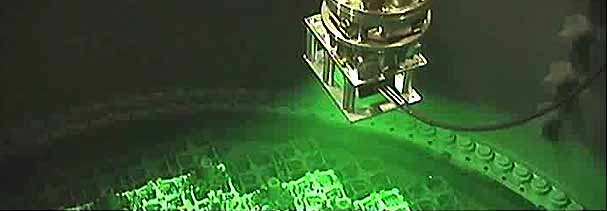

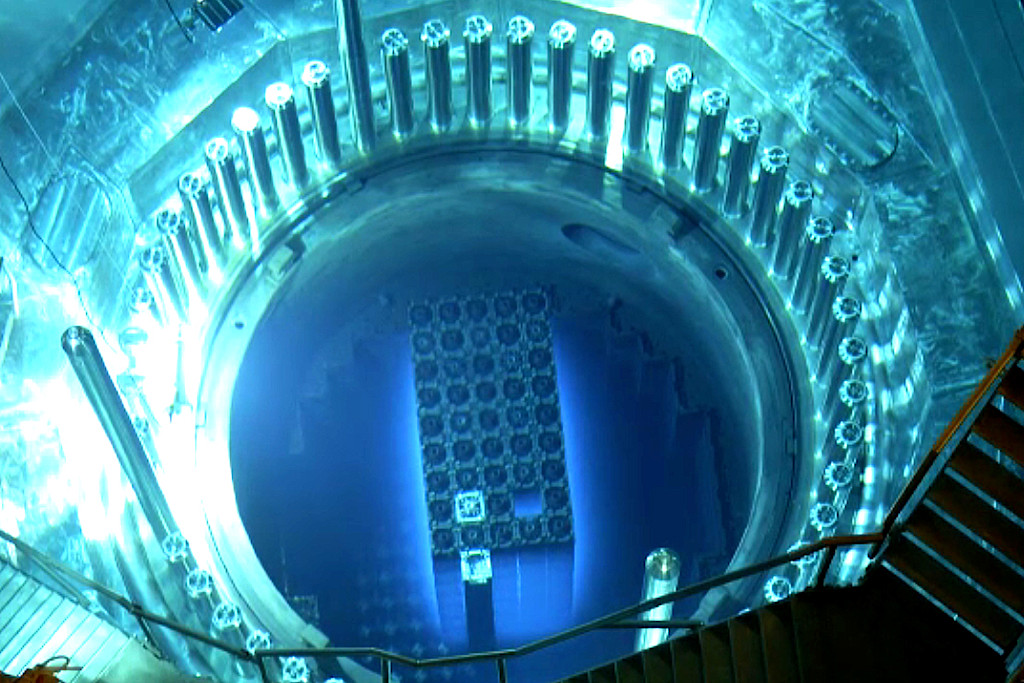

The Core Verification System is the primary application and interface used to perform a complete core mapping in approximately one

hour or even less.

|

NM200E fuel assembly

mapping head

|

|

The NM200UW Nuclear Underwater Laser Scanner delivers

precise, non-contact dimensional measurements in the underwater radiation

environments found in BWR and PWR vessels and in the pools, or other underwater

plant locations. The system combines rugged, industrial-grade hardware and

electronics with sophisticated software to enable the generation of fully

measurable CAD models from dense and accurate point clouds.

*This technology enabled Exelon Nuclear to win

the Nuclear Energy Institute's 2012 Top Industry Practice (TIP) Award in the

Materials and Services Category for

“Laser

Scanning within a BWR Vessel.”

|

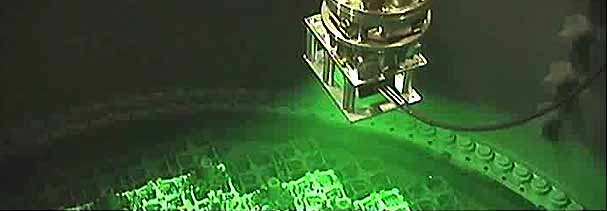

The dense point cloud from a scanned main wedge within a BWR annulus enabled the rendering of a precise, measurable CAD file.

|

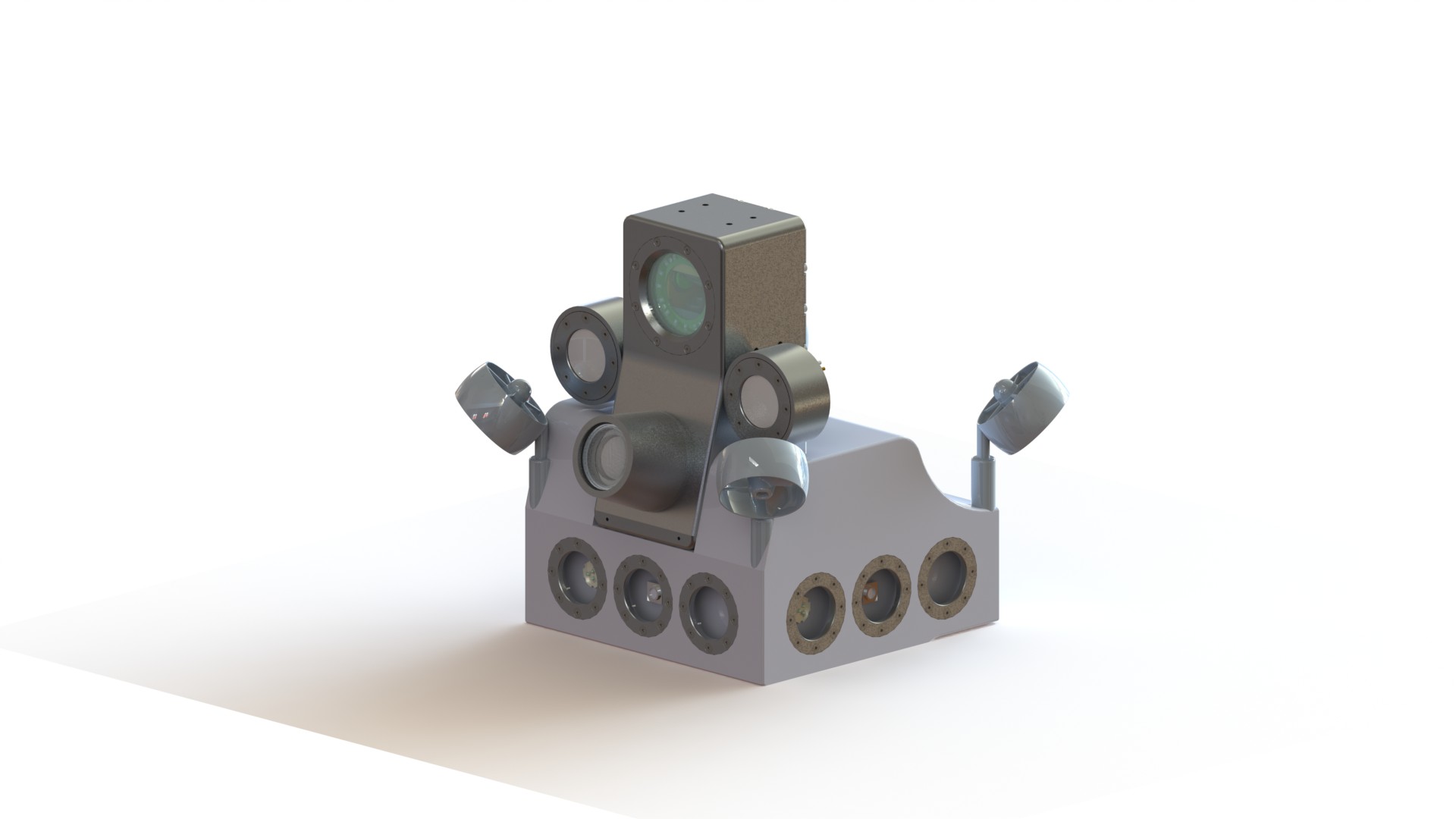

NM200UW Nuclear Underwater Laser Scanner

|

|

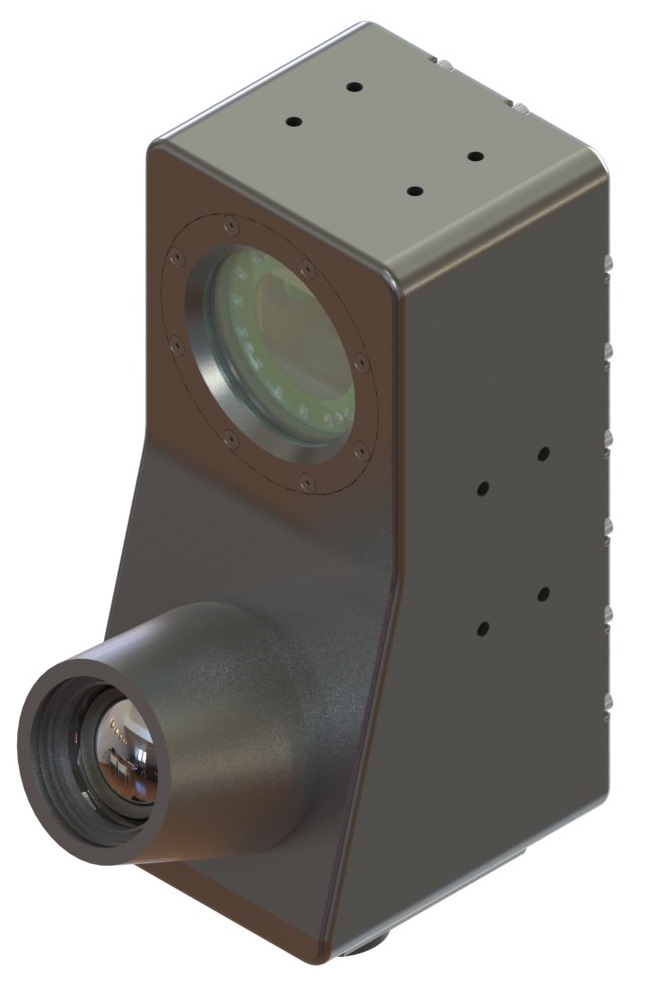

The NM200EVT-1 Nuclear Underwater Laser Scanner combines the

underwater scanning CAD data of the NM200UW scanner with Color Enhanced Visual Inspection capabilities to meet MRP/ASME Section XI requirements.

Along with MRP227 Visual Inspections the system combines industrial-grade radiation resistant hardware and

electronics with Newton's sophisticated software to enable the generation of fully

measurable CAD models from dense and accurate point clouds.

*This technology enabled Exelon Nuclear to win

the Nuclear Energy Institute's 2012 Top Industry Practice (TIP) Award in the

Materials and Services Category for

“Laser

Scanning within a BWR Vessel.”

|

Scanning Reactor Internals enables the rendering of a precise, measurable CAD file along with MRP227 Enhanced Vision Inspection.

|

NM200UW Nuclear Underwater Laser Scanner

|

|

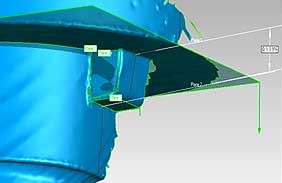

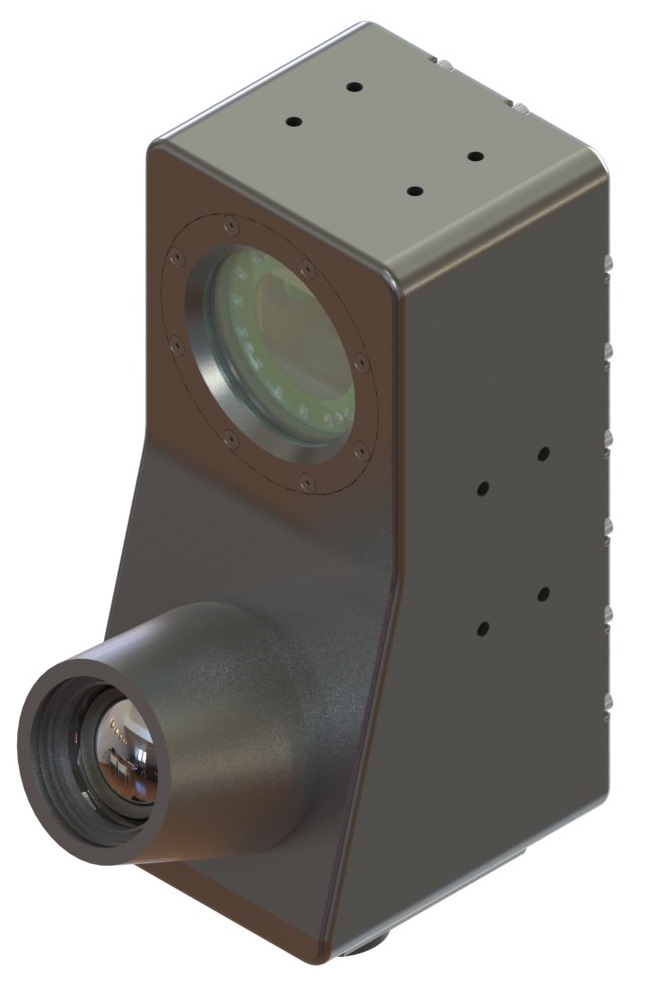

The NM260UW Nuclear Underwater Laser Scanner captures precise dimensional measurements in underwater radiation environments to provide precise, reliable and efficient dimensioning of as-built features, as well as to track cycle-to-cycle degradation in BWR and PWR vessels, cooling pools, or other underwater plant locations. The system as a demonstrated accuracy of 0.005" (0.127mm) or better and combines rugged, industrial-grade hardware and electronics with sophisticated software to enable the generation of fully measurable CAD models from dense and accurate point clouds.

|

Non-contact measurements of PWR or BWR internals.

|

NM260UW Nuclear Underwater Laser Scanner

|

|

The NM300UW Nuclear Underwater Laser Scanner delivers

precise, non-contact dimensional measurements in the underwater radiation

environments found in BWR and PWR vessels and in the pools, or other underwater

plant locations. The system combines rugged, industrial-grade hardware and

electronics with sophisticated software to enable the generation of fully

measurable CAD models from dense and accurate point clouds.

*This technology enabled Exelon Nuclear to win

the Nuclear Energy Institute's 2012 Top Industry Practice (TIP) Award in the

Materials and Services Category for

“Laser

Scanning within a BWR Vessel.”

|

The dense point cloud from a scanned main wedge within a BWR annulus enabled the rendering of a precise, measurable CAD file.

|

NM300UW Nuclear Underwater Laser Scanner

|

|

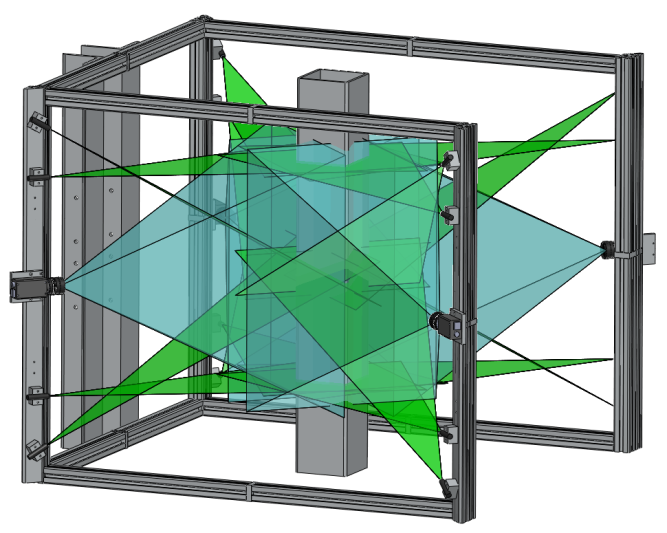

Newton Labs Model SW1000 State of the Art Underwater Drone Platform

for deployment of the NM200EVT-1 Laser Scanner to perform MRP227 and ASME Section X1 inspections.

Advanced Newton developed position holding software, similar to the software used on air drones,

controls thrusters for exact placement and stability to perform the most critical EVT-1 inspections and laser scan measurements.

Newton's SW1000 Underwater Drone can be pre-programed to inspect over 90% of MRP-227 and ASME Section XI required inspections and physical

measurement thus removing a significant load from the drone operator.

*This technology enabled Exelon Nuclear to win

the Nuclear Energy Institute's 2012 Top Industry Practice (TIP) Award in the

Materials and Services Category for

“Laser

Scanning within a BWR Vessel.”

|

Newton's SW1000 Underwater Drone can deliver the NM200EVT-1 to scan structures and is programmable.

|

NM200UW Nuclear Underwater Laser Scanner

|

|

The QUAD400UW Fuel Bundle Inspection System is

deployed in the spent fuel pool to measure and detect bowing, twisting, and finer defects in spent fuel.

Fuel assemblies can be scanned and measured in less than 40 seconds and result in instant CAD models to allow for immediate disposition decisions.

|

All four sides of the fuel bundle are scanned to detect bowing or twisting and other defects

|

QUAD400UW

Fuel Bundle Inspection in service

|

|

The Inspector Underwater In-Tank Robot is

a highly maneuverable, semi-autonomous robotic platform that

enables plant owners to meet the requirements of the Nuclear Energy

Institute for tank inspection in accordance with NEI 09-14. An Inspector

system has the ability to deploy a variety of advanced nondestructive evaluation

(NDE) sensors over 90% of a tank floor and to map the position of any indications

with an accuracy of 1/8th inch (3 mm). Surveys can be performed with

the tank full or dry. An Inspector system is composed of the robot, an in-tank,

hatch-mounted global positioning camera assembly and the operator's console.

|

A vertically indexed arm mounted on the robot is shown fitted with an ultrasonic probe unit. A second, adjacent arm is seen in the fully raised position.

|

Inspector Underwater

In-Tank Robot

|

|

The Surveyor Robot is

a highly flexible and fully autonomous or semi-autonomous robotic platform that

allows utilities to inspect or perform operations in nuclear facilities. The robot

has built in high resolution pictures and laser scanners. The Surveyor robot

can also carry various arms and can integrate the data from many other different sensors including

ultrasound, eddy current, ACFM and other sensors. The Surveyor can be equipped with

wheels, Mecanum wheels, tracks and propeller pods or various combinations of motive

options to provide required mobility. Surveyor operates in air or underwater.

|

The Surveyor can function fully autonomously or under operator control.

|

The Surveyor operating Underwater

|

The Reactor Pressure Vessel Inspection Robot is

a reactor barrel measurement tool. The Newton RPV Inspection Tool measures the condition of the reactor barrel with various

sensors and produces significant data including CAD

models of the reactor barrel and the lower internals. It also measures ovality of the

reactor barrel as well as surface condition. The Newton RPV tool can be equipped with

Laser Scanners, Phased Array Ultrasound, Eddy Current and ACFM sensors.

|

A vertically indexed arm mounted on the robot is shown fitted with a senor head containing underwater laser scanners and

ultrasonic probes to perform full barrel examinations.

|

The RPV Sensor Head

|

Newton collaborates with Mike Baron at

|

And with Keith Moser

|

|