NM200EVT-1 Nuclear Underwater Laser Scanner with Enhanced Visual Inspection

Developed Specifically for the Nuclear Power Industry to Satisfy MRP/ASME Section XI Inspections

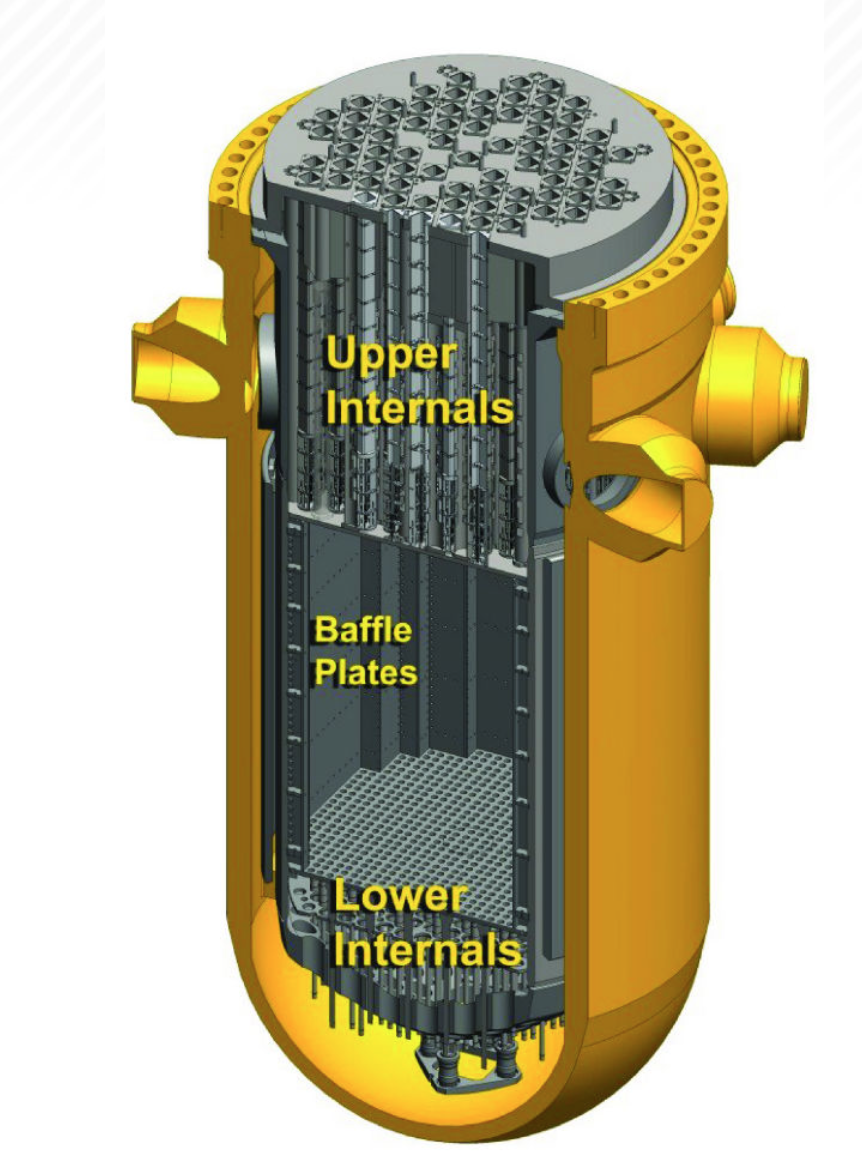

The NM200EVT-1 nuclear underwater laser scanner is a new accompaniment to Newton's landmark underwater nuclear scanning technology. This new tool adds color EVT-1 Enhanced Visual (as well as VT-1 and VT-3) capability to the NM200UW nuclear underwater scanner.

The NM200EVT-1 system combines rugged, industrial-grade hardware and electronics with sophisticated, Newton-developed software that mitigates the disruption of turbulence, heat, and radioactivity characteristics of the in-vessel environment.

The laser scanner has a demonstrated accuracy of 0.003" (0.076mm) or better, and is designed to work in concert with industry standard, three-dimensional software, producing a point cloud output so dense and detailed that a fully measurable CAD model can be generated.

The capability of the NM200EVT-1 to provide precise, reliable and efficient dimensioning of as-built features as well as providing MRP-227 Enhanced Visual Inspection to track cycle-to-cycle degradation can be important to nuclear utility operators.

Components of the NM200EVT-1 system:

- The NM200VT-1 scanning head encloses a ultra-high resolution video camera and a controllable output high-intensity LED ring array

- The NM200EVT-1 camera is native 2048 X 1536- 3 Megapixel high resolution color camera that easily exceeds the requirements of EVT-1.

- The NM200VT-1 light is a fully controllable output high-intensity white LED ring array

- The console unit contains the scanner control unit, a rack-mounted PC, flat panel screen and keyboard

- Newton Labs underwater scanning software

- Components are housed in two, high impact airline-transportable luggage cases

- Directional and speed controls for the optional PT200UW Pan-Tilt Arm come pre-installed in NM200UW consoles.

- The power/data umbilical cable is gel-filled with LLDPE polyurethane jacket and a rated yield point of 80 lb/ft (11 Kg/M) with a standard length of 150 ft. (46 m); lengths up to 300 ft. (91 m) may be special ordered.

NM200UW Deployment

The January-February 2012 edition of the Nuclear Plant Journal published a detailed article about the Newton NM200UW capturing precise measurements in a difficult BWR location within a short period. Read the article HERE.