Inspector: A Versatile Sensor Platform

Precisely inspects the integrity of tank floors.

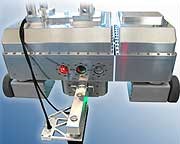

An indexed sensor arm with an ultrasonic probe unit is shown here attached to the port side of the robot, one of three possible mounting positions. Front-mounted arms enable sensors to be maneuvered into the corners of quadrilateral tanks.

IInspector robots are designed to accommodate

several mounting options for non-destructive evaluation (NDE) equipment, enabling them to map and

inspect over 90% of a tank floor, including inspecting within very

close proximity of the tank wall edge.

The sensor mounting options include:

- Indexable, twin-arm sensor mounting module

- Front-end mounting bar with multi-functional holes extending port and starboard to allow for mounting of optional tank bottom sweepers or other devices

- Low-slung, arm-mounted equipment plate on starboard side

- Top deck can accommodate additional sensor mounting

- Additional options include tank bottom cleaner, specialized sensors, environmental mapping and robotic arms

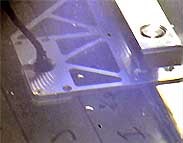

A standard sensor compliment consists of phased array UT and/or eddy current systems, as well as the on-board fore and aft, side-to-side and down-looking video inspection, in addition to down-looking underwater laser scanning.

Inspector robots offer plant operators the most advanced

nondestructive evaluation (NDE) tank inspection services currently

available in the nuclear industry. The selection of inspection services

include:

- Examination of water-filled or dry tanks

- Repair of water-filled or dry tanks

- Underwater laser scanning and 3D modeling

- Phased array UT and eddy current NDE surveys

- Real-time video inspection

- Weld inspection and mapping

- Tank cleaning

- Weld inspection vacuum box

Newton Labs has partnered with Sonic Systems to provide the non-destructive (NDE) inspection technology for the Newton Underwater Nuclear Robotic tank inspection. This combined service will be the most advanced underwater NDE tank inspection and robotic repair service currently available in the nuclear industry. This service is now available for both water and diesel tanks.

Read the press release ▶