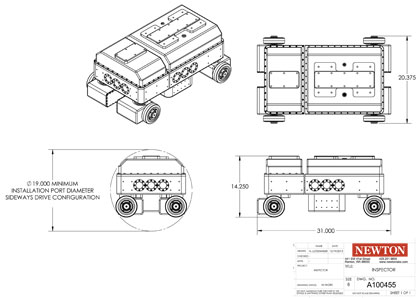

Inspector: Underwater In-Tank Assessor Robot

Positions NDE probes and maps tanks with 1/8 inch (3 mm) precision

The Inspector is a highly maneuverable robotic platform and system designed to locate and map tank bottom defects with +/- 1/8 inch (3mm) accuracy in water-filled or dry storage units as large as 50 feet (15 m) in diameter. The Inspector system is composed of the robot, an in-tank, hatch-mounted global positioning camera assembly and the operator's console.

The features of the Inspector system include:

- Five on-board color video cameras

- Overhead precision navigation system

- On-board down-looking video capture

- Highly maneuverable four-wheel steering

- Four wheel independent drive motor system

- On-board downward-facing 3D laser scanner

- Split chassis design provides constant all-wheel contact

- Virtual view User Interface enables precise manual control

- Laser range finders on all four side for precise positioning

- Sediment-clearing rotating brush assembly (several designs)

- Real-time video imaging: forward / rearward / left side / right side

| Inspector System Specifications | |

| Elements | Details |

| Length: | 31 in. (78,7 cm) |

| Width: | 20.38 in. (15.75 in. for tank insertion) (52 cm & 40 cm) |

| Height (chassis): | 14.25 in. (36 cm) |

| Weight (in air): | 245 lbs. (111 kg) |

| Weight (in water); | 100 lbs. (45 kg) |

| Construction (chassis): | Machined from solid billets of 6061-T6 aluminum stock |

| Video cameras: | 5 ea. on-board high-resolution

color |

| Scanning laser power: | 35 MW |

| Scanning laser resolution: | 0.01 in. (0,3 mm) |

| Rangefinder laser power: | 7 MW ea. |

| LED arrays | 4 ea.- chassis perimeter

- 705 lumens ea. |

| Voltage input to control unit | 100 to 240 VAC 50 to 60 cycles |

| Underwater temp. range | 32° to 122° F (0° to 50° C) |

| Top speed (all directions) | In excess of 6 in. (15,2 cm) per second |

Newton Labs has partnered with Sonic Systems to provide the non-destructive (NDE) inspection technology for the Newton Underwater Nuclear Robotic tank inspection. This combined service will be the most advanced underwater NDE tank inspection and robotic repair service currently available in the nuclear industry. This service is now available for both water and diesel tanks.

Read the press release ▶