Automotive Weather Strip Laser Inspection

The Challenge:

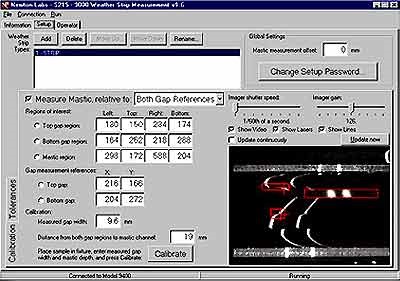

The challenge was to determine the style of a rubber automotive deck lid seal manufactured, and then measure the accuracy of the resulting extrusion. Each extruded seal had a complex configuration, making identification and measurement difficult. In addition, the manufacturer required the sensing and measuring of the amount of mastic that is pre-applied deep inside the convolutions of the extruded weather seals.

The Solution:

Newton engineers developed a non-contact measurement system using a laser line and an area scan camera. The laser line is normally straight, but to the camera the line appears deformed as it strikes a contoured 3D object. The pattern of the deformed line creates a unique signature of that object. This data set is compared by the vision system to a known good profile for each of the styles of weather strip.

The depth of the hidden mastic is measured by similar changes to the same profile in the region of mastic application because the weather strip would measure thicker or thinner, depending if too much or too little mastic had been applied.