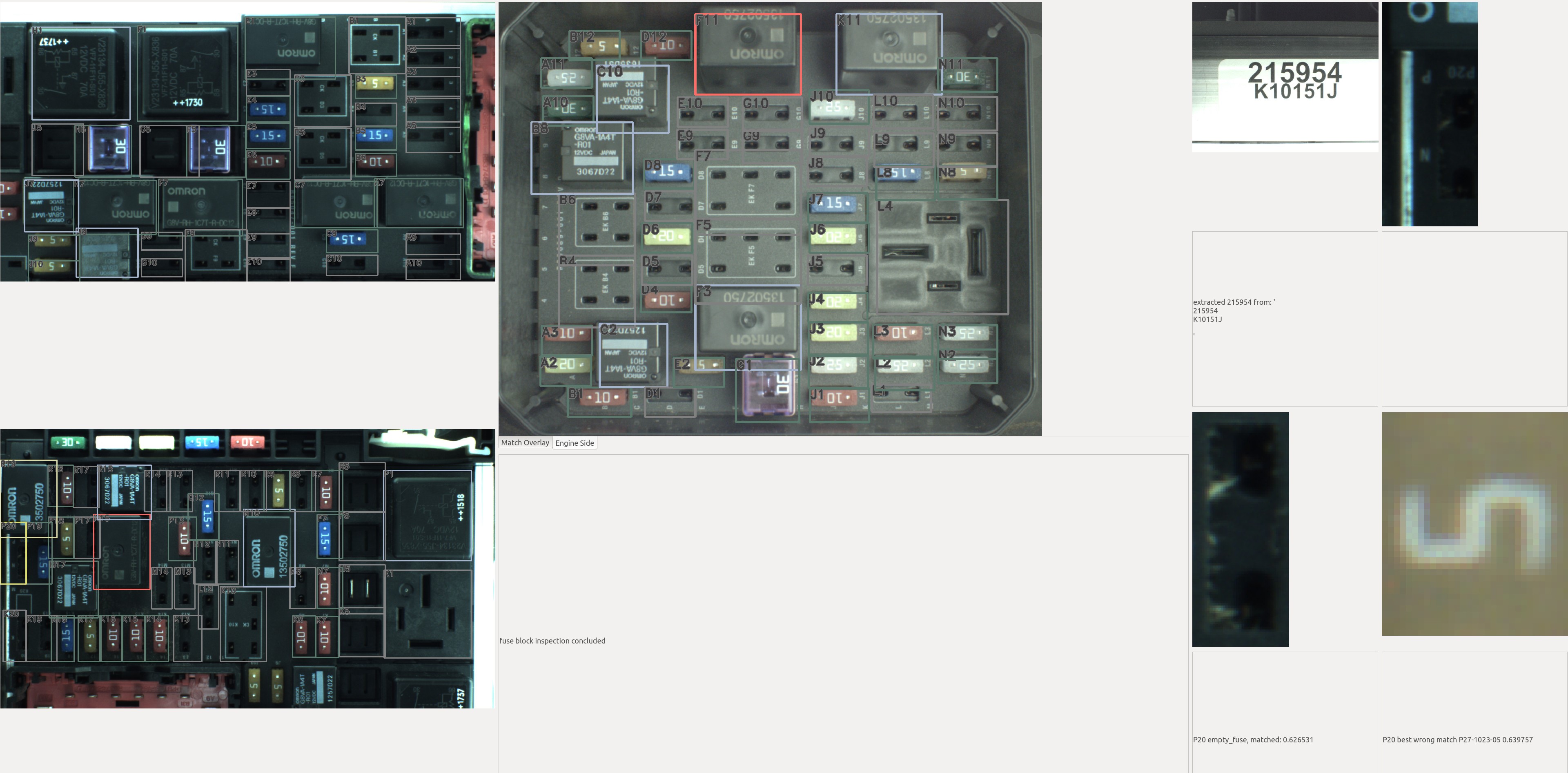

Newton Labs Class 8 Heavy Truck PDC Fuse Block Inspection System

Machine vision with advanced, automatic feature recognition.

The Reqirement:

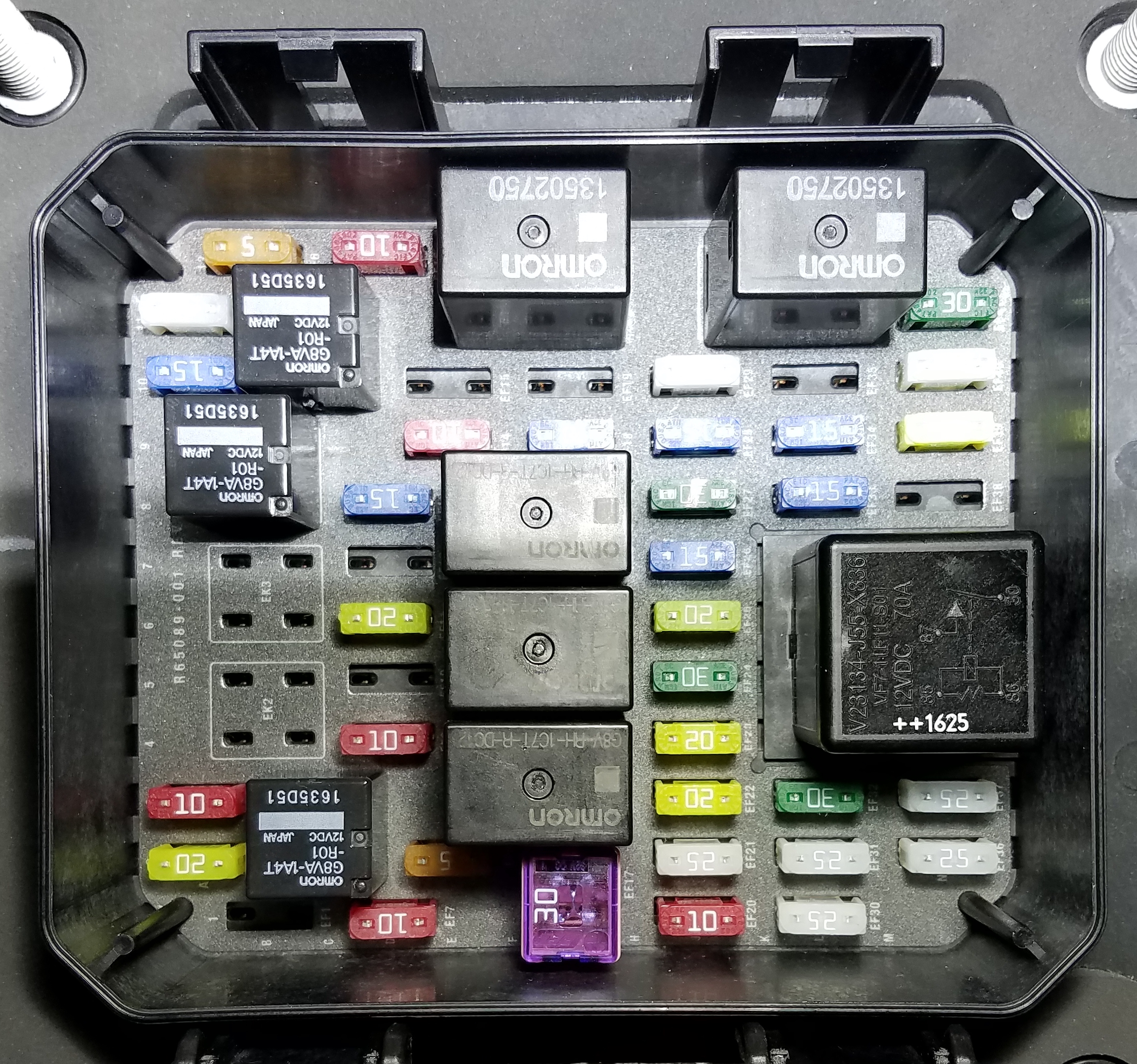

Riffle Machine, a supplier to a heavy duty truck assembly plant, required a Fuse Box Verification system to ensure absolute accuracy, replace human inspectors and provide significant cost savings. Newton engineers developed a system for Riffle that was able to read the chassis number on the fuse box and then interrogate the plant electronic system to determine the correct fuses and relays were present and to determine they had been inserted into the correct placements.

The Solution:

A machine vision system was developed to read the chassis number on individual fuse boxes and automatically configure its setup to detect if the box style was correct and if the fuse and relay content, text and placement matched the requirement of the build description. The Newton system does not use color matching but instead actually reads the printed numbers on the fuses and relays to confirm they matched the plant electronic build to ensure accuracy; essential given the wide variation in colors present in fuses supplied by the fuse manufacturers.

The Newton Fuse Box Verfication system simply requires the operator to place the fuse box into a drawer on the front the machine. The Verification Machine then immediately outputs a Good or Bad reading showing the errors on the screen if any exist. Optionally it also notifies management of errors by lighting the red strobe mounted on the top of the unit.