Non-Contact Gauging Technology

Non-contact gauging involves performing highly accurate measurements using machine vision, while maintaining a minimum stand-off distance between the measurement system and the product. It replaces error-prone procedures such as using calipers, test shims, or template gauges to manually check the physical dimensions of an item.

Simplified Measurement

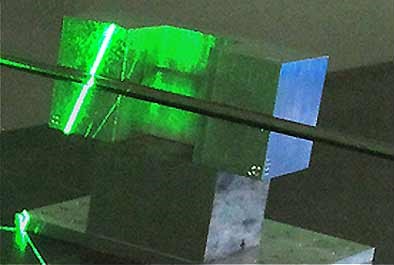

As an added benefit, non-contact gauging retains (or improves upon) accuracy of these techniques, while eliminating the complications that arise from physical contact. In conjunction with area scan cameras, Newton has developed custom engineered illumination, as well as laser profiling and structured lighting, to perform highly accurate and rapid gauging of a variety of products.