Press Die Vision System Prevents Error Coins

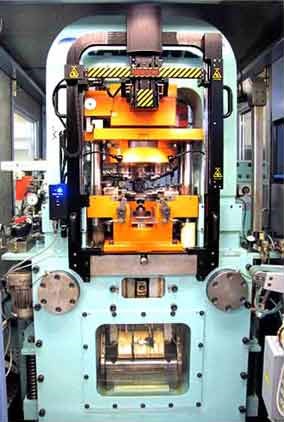

The Press Die Vision System (PDVS), developed and manufactured by Newton Labs, combines robotic mechanism with optics, custom software and machine vision technology to detect and prevent the production of error coins known as "mule coins". Working in collaboration with the United States Mint at San Francisco and the press manufacturer, the PDVS was designed to prevent the press from operating if an incorrect die pair were present, or if the correct die pair were not properly installed and aligned. This quality control mechanism gives press operators a guarantee that the production of mule coins from mismatched or misaligned dies will not occur. Uniquely DesignedThe PDVS is an important addition to mint operations because mule coins, even if caught before release, are considered a serious error and lead to downtime in press operations. The PDVS is uniquely designed to automatically prevent the production of an error, not simply to detect post-production deformities. |

The PDVS installed on a press at the U.S. Mint.

Place your cursor on the photo to see highlighted elements

of the Newton vision system. |

Features of the PDVS:

|

CLICK

HERE TO READ about the deployment of the Press Die Vision

System at the San Francisco Mint in the June 11, 2012 edition

of Coin World magazine.

|