High-Speed Fruit Cup Lid Inspection

Line scan technology without major conveyor modification.

The Challenge:

The challenge was to detect and confirm the integrity of the thermoformed lid seal on plastic cups of mixed fruit snacks as they passed on a high-speed conveyor at 10 units per second. When defects occurred, they appeared as minute, clear bubbles and blisters under the thin clear plastic seal around the rim of the cup.

The Solution:

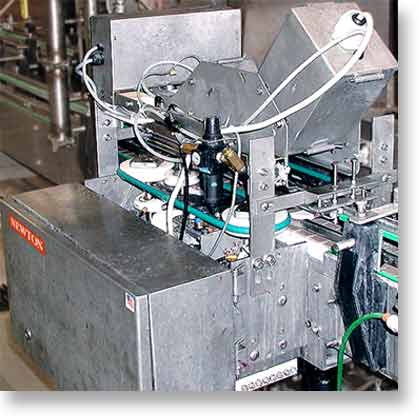

Newton engineers developed a solution combining mechanics with a line scan imaging system that did not require the customer to make modifications to the conveyor. The unit bridged over the conveyor and featured a pair of soft, narrow horizontal looping belts that faced each other across the conveyor and were driven at matching speeds, but in opposite directions. The fruit cups passing between the moving belts were lightly squeezed, causing them to spin in place while still moving at conveyor speed.

The line scan camera, which was mounted on a short, movable slide assembly above the conveyor, would quickly shuttle back and forth along the direction of travel of the product. As an individual cup traveled down the conveyor and was engaged by the twin belts, the line scan camera followed it from above and captured the full 360 degree view of the lid seal as it spun around. The high resolution and frame rate of the line scan camera was able to image each circular seal as a linear strip.