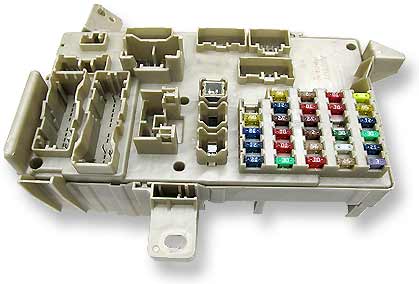

Automotive Electric Fuse Block Inspection

Machine vision with advanced, automatic feature recognition.

The Challenge:

Auto and truck assembly plants each produce many different models that are interspersed throughout different assembly lines. Subcontracting auto-electric factories, often in different states, pre-assemble automotive fuse boxes and populate them with fuses and relays for specific makes and models of vehicles. Factory planners need to produce specific fuse boxes in the same order that the cars and trucks will later be assembled at remote plants. Newton engineers were asked to develop a system able to read the code that determined which model type of fuse box was presented to our sensors and verify that the correct components for that vehicle were present and assembled correctly.

The Solution:

A machine vision system was developed to read the bar code of individual fuse boxes and automatically configure its setup to detect if the box style was correct and if the fuse and relay content, color, text and placement matched the requirement of the build description. The Newton system incorporated a considerable degree of automatic feature recognition without the necessity of having to train each configuration into a database. This was a significant achievement, given the large variation of box appearances and configurations.