Magnet Blanks Inspection and Sorting Machine

Performing 20 individual inspections on 600 units per hour.

The Challenge:

A manufacturer of molded permanent magnets for electrical motors found that the pre-magnetized magnet blanks were often damaged during the phase of production that included grinding to shape the edges. The manufacturer wanted to automate the process of inspecting each magnet blank for the presence of cracks, chips, foreign material, or out-of-tolerance dimensions and have them removed from the production line.

The Solution:

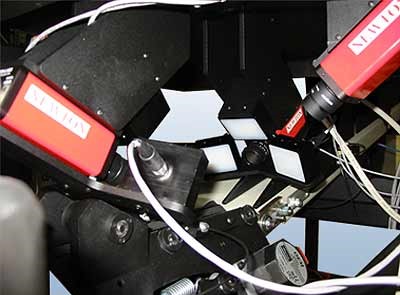

Newton engineers developed a stand-alone unit containing a machine vision system with two inspection stations. The freshly-made, pre-magnetized blanks, shaped like a crescent section of a barrel, emerged from their final wash and entered the machine at a rate of one per second.

Through a series of chutes and conveyor belts, the blanks were separated, evenly spaced and oriented length-wise with the "inside" crescent face down. At the first inspection point a bank of four area scan cameras inspected the outside radius and end chamfers. The magnet blank was then conveyed forward and flipped over to a present the inside radius and chamfers to another bank of four cameras. After over 20 individual inspections, an individual blank was then either rejected or sorted for packaging.