Features of NM200E Core Verification Software with Artificial Intelligence and Machine Learning

|

|

|

|

|

|

|

|

|

|

|

|

The accuracy of the NM200E Core Verification System is based on proprietary Newton-developed Artificial Intelligence

and Machine Learning software algorithms that accurately identify and measure the positions of all fuel assemblies in a PWR reactor and compares

them with ideal positions (supplied by the reactor operators); even in the presence of significant thermals. The Newton NM200E Core Verification System

does not attempt to remove the thermals; instead it utilizes the distorted pictures combined with sophisticated AI/Machine Learning to precisely locate the

bundle position.

The sophisticated AI/Machine Learning software enables the precise global mapping of fuel assembly positions, including any degree of misalignment or

nozzle rotation, while compensating for the visually distorting issues of thermal turbulence and light refraction.

NM200Esoftware determines the positions of Westinghouse and AREVA PWR fuel assemblies based in part upon s-hole positions and that information combined with

Newton's proprietary Machine Learning and Artificial Intelligence allow for determining precise bundle position.

It is also able to map the

more symmetrical Babcock and Wilcox nozzles.

There are two software applications that are provided with the NM200E system:

- The utility application that allows the user to easily input all desired core and mapping specifications and

- The mapping

application with the main user interface to guide the user through the core mapping operation.

Both applications run on the control box utilizing the Ubuntu Linux operating system. No prior knowledge of the Linux operation

system is required to operate the system.

Core Layout Utility Application

The Core Layout Utility has the following functions:

- Specify layout patterns for used and new fuel assemblies

- Specify gaps globally, or on a per-row or per-column basis

- Specify the North cardinal direction in relation to the core layout

- Specify the mapping head positions (stops) to be used for the core mapping

- Modify global settings such as the site name, label order and nozzle dimensions

Core Mapping Application

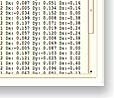

The Core Verification System is the primary application and interface used to perform a core mapping. During deployment, it displays processed images from the mapping head, and guides the operator through the mapping procedure by providing instructions and feedback on the current status of the process.

On the NM200E operator's console the actual s-hole positions of individual nozzles are graphically superimposed upon the "ideal" or "design" locations. Out-of-tolerance s-holes are immediately apparent and their precise locations are digitally recorded for future reference.