Potato Chip Container Inspection With UV Light

The Challenge:

The challenge was to inspect the inside of black plastic cylinders used for packaging a line of potato chips. To insure a fresh tasting product, the manufacturer had a transparent chemical sprayed inside the containers to form a barrier against oxygen. The problem was that the clear oxygen barrier spray could be over-applied, resulting in the liquid dripping and running inside the container. Additionally, some of the drips would dry and be knocked from the can wall during shipment, forming particles to be found among the chips by consumers.

The Solution:

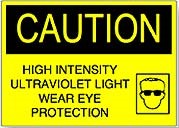

Newton engineers discovered that over-concentrations of the oxygen barrier material fluoresced when exposed to a deep UV light source. Newton placed cameras and illuminators in an arraignment on the assembly line to view inside the containers prior to being loaded with chips. The entire system would only respond when an excess of the barrier material exceeded a certain level.