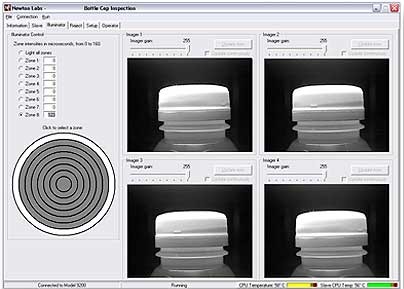

Automated Plastic Bottle Cap Inspection

Measuring for correctly torqued caps at 20 bottles per second.

The Challenge:

The challenge was that PET (polyethylene terephthalate, a plastic resin and a form of polyester) bottles and caps have molded-in marks that allow inspectors to check that the caps are installed to the correct torque. The vision system needed to find and measure the radial distance between the two marks at a rate of 20 units per second.

The Solution:

Newton engineers developed a custom overhead illuminator that could electrically alter the diameter of its light-pool and the lumens of light that it emitted to allow for a repeatable and constant shadow to form in the areas of the molded in marks. Circumferential cameras positioned around the cap imaged a complete 360 degrees.